When considering fenestration and enclosure systems for architectural projects, it’s important to think bigger than just the material they’re made from. The way a window or enclosure is constructed affects not only how it looks, but also how it performs on a practical level.

Prior to the industrial revolution, window frames were typically made by a blacksmith or carpenter using a slow, handcrafted process – and at Renaissance Bronze, we pay homage to this craftsmanship in our own manufacturing process.

This is particularly evident in the way our bronze window and enclosure frames are constructed, drawing on traditional methods pioneered by master craftsmen with a focus on beauty and integrity – not speed or convenience. Let’s take a closer look at how our windows are built.

What are Renaissance Bronze Windows and Enclosures Made From?

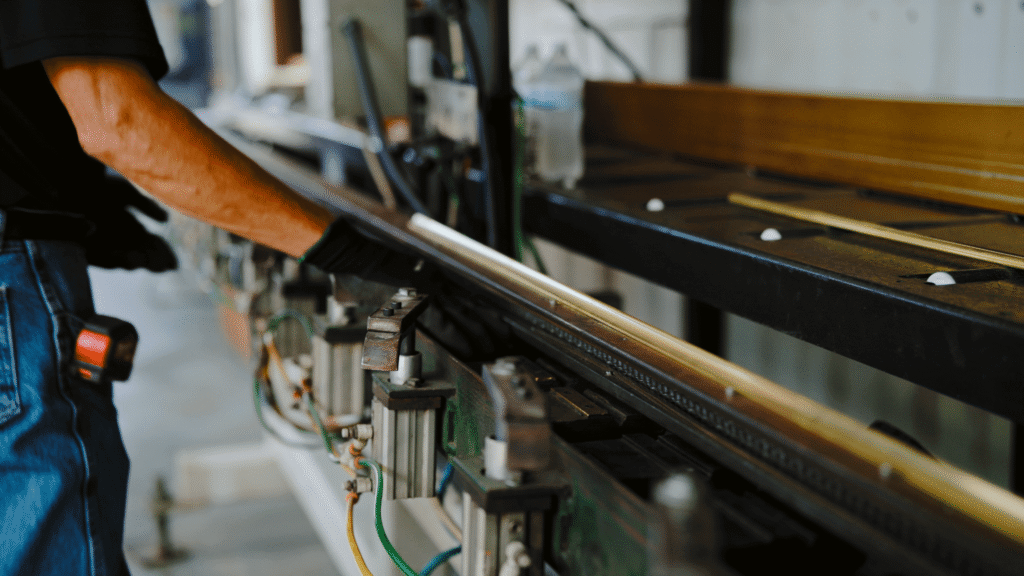

Every Renaissance window or enclosure system begins its life as a series of solid bronze extrusions, primarily sourced from a specialist bronze extruder in Europe. The extrusion process involves heating a solid bronze block (known as a billet) and then pushing it under intense pressure through a mold or die to form a long, slender piece of bronze with a specific profile.

Bronze has very good extrudability, producing extremely fine, detailed forms. The extrusions are designed to interlock with extreme precision to form the structure of the window frame, muntin bars, and glass bead.

Thermally Broken Frames

A key part of this system is our integrated thermal break, which uses polyamide strips that fit precisely into grooves in the extrusions, separating the internal part of the window from the external part so that heat and cold cannot transfer between them.

Durable & Refinishable

Because our bronze is extruded as opposed to rolled (common with other windows and materials like steel), the frame components are solid, not hollow. This means they are highly resistant to dents across their lifespan, and also that they can be refinished to eliminate any scratches that occur over time, without any loss of strength.

How Are Renaissance Bronze Window Frames Joined Together?

The majority of metal windows are joined together at the corners with brazed or welded miter joints. This means the frames are mitered or cut on a 45-degree angle, and then the seam is joined in a welding or brazing process.

Any welding or brazing process involves extremely high temperatures that can cause the metal frame to warp. It can also lead to weakness in the base metal where it gets contaminated with the filler metal at the joint. Finally, brazing creates a visible ‘seam’ where the components are joined together by the molten filler metal.

Coped & Mechanically Fastened Window Frames

To avoid these practical and aesthetic issues, Renaissance Bronze windows and enclosures are joined using a method called ‘coping’. This technique is borrowed from the carpentry industry and was traditionally used to join wooden window frames for a seamless look that is much stronger than miter joints.

Coped joints require additional workmanship during the manufacturing phase, but deliver a much more polished and refined look on the finished frames, while also adding some key benefits in terms of practical performance.

The square ends of our bronze extrusions are precision machined so they interlock perfectly for a virtually invisible join that is never exposed to heat stress. This means that as well as looking beautiful, our frames remain perfectly square, and deliver durable performance for many decades.

Coped and fastened joints have the added benefit of being flexible, unlike welded joints which are rigid – this means that in the event of building movement over time, they won’t develop stress cracks. They can also perform much better with window openings that are irregular, for example on restoration projects.

What Fasteners Are Used to Manufacture Bronze Windows?

Once our coped frames are fitted together, they’re held in place with mechanical fastenings – never welded or brazed. The strength of the joint is actually in the coped frame itself, and we simply use stainless steel screws to hold everything securely in place. These screws are fitted to the edge of the window or enclosure frame so they are invisible once it’s installed. Having the windows coped and mechanically fastened also makes it simple to service or reglaze the windows if required – they can be taken apart and reassembled, with no need to break the joints and no ugly rewelding.

What’s the Role of Glazing in Bronze Window Assembly?

Glazing is the final part of the bronze window construction process – and it’s a key element in the structure of our products. We use a DOW 995 structural silicone to wet glaze our windows and enclosures, which means that once the glass is fitted, it contributes to the supreme strength and squareness of our systems.

To explain the science a little, Dow 995 is a neutral-curing silicone sealant, which means the by-products of the curing process won’t affect the color or structure of the bronze substrate.

As the sealant cures, siloxane chains in the silicone react chemically with the bronze and each other, forming a cross-linked bond structure that allows for strong adhesion but also +/-50% movement capacity. This results in a window or enclosure panel that is supremely strong and square, with the capacity to cope with movement in transit and from external forces such as wind.

The Renaissance Assurance on Quality

Every Renaissance product is designed and built by hand in our San Antonio workshop using a time-honored small-batch process designed to deliver distinctive aesthetics and uncompromising structural integrity. Our products are heritage grade, with an estimated lifespan well in excess of 150 years.

Thoughtful design, proprietary installation systems, and dealer partnerships mean there’s no need to have a specialist installer on site – everything needed to fit the products is included with the shipment, and we provide comprehensive aftercare support, including expert consultancy for unique or challenging installs.

We offer a full, lifetime warranty on solid bronze products found to be defective in materials or workmanship (including parts and labor) for as long as the original purchaser owns their home. Additionally, our glass carries a warranty of up to 10 years.

For further information about the construction or installation of our bronze products, get in touch.