As an architect, it’s your job to care about the finer details of a construction project; to give careful consideration to all the elements and materials that eventually come together to create the final look of a building.

When it comes to fenestration design there are lots of available options. Most architects shudder at the mere mention of uPVC, but with timber and a variety of metal options also available, it’s important to understand the nuances of the different materials so you can make a considered choice.

In this blog, we’re going back to basics on fenestration – what are the main types of windows available, and where are they typically specified? What’s the basic anatomy of a metal window – and why would you stretch your imagination (and your client’s budget) in order to specify bronze? Let’s take a look.

What are the main window types?

Windows fall into two basic types – casement windows and sliding sash windows (sometimes called double hung windows).

Casement windows

Casement windows are probably the more common of the two and are opened via hinged panels. Classic casement windows are hinged at the side, while awning casements are hinged at the top. Casement windows can also be fixed, which means they don’t open.

Casement windows can be made from all the common window materials including timber, plastic and metal. They have a key advantage in that they can be constructed in almost any size, which is why casement windows became so popular in factory buildings during the industrial revolution, and why the classic ‘factory window’ – a large casement made of multiple small panes to maximize light – is still considered a design classic today. All of our bronze windows are casement windows, and we offer a variety of hinge systems.

Sliding sash windows

Sliding sash windows have top and bottom sections that are hung on a system of cords and weights. They open and close simply by sliding the window up and down.

Sliding sash windows are most often made from timber, because this makes it easy to conceal the cords and weights inside the frame, but they can also be made from materials like uPVC. Wooden sliding sash windows are limited in terms of size due to their sheer weight. The frames themselves are quite chunky and traditional-looking and therefore they are most often specified for classic Georgian and Edwardian-style architecture and country-style homes.

A glossary of window terms

Window frames are made up of various parts, each with their own specific names. While some parts are common to all types of window, other parts may be specific to certain window styles. Here’s a glossary of some common window terms:

Jamb: The vertical sections of the main window frame

Rail: The horizontal sections of the main window, connecting the jambs to form a square or rectangle

Mullion: Vertical or horizontal dividers that split a window into separate sections. Usually thicker than jambs and often used to create visual interest

Transom: A small window at the top of a larger window frame or above a door, sometimes capable of opening independently.

Sidelite: A window down the side of a door or large casement window, often separated by mullions. Not usually capable of opening.

Muntin: Metal bars set into the main frame of the window to divide it into smaller apertures. Genuine muntins physically divide the glass into smaller panes.

Lites: A word to describe each individual section of glazing on a window, a lite can refer to a small, single pane or a group of panes that form one unit.

Why specify bronze windows?

Steel remains the most popular choice for contemporary, factory-style and large-scale casement windows today. This is because refinements in the manufacturing process and ready availability of the raw materials made it easy for manufacturers to scale up mass production of steel window frames from the mid 20th century onwards.

But mass production means that when it comes to steel, your freedom as an architect will be limited by what’s already available in the marketplace – and that leads many design professionals to consider bronze as a more versatile, bespoke option for fenestration.

How we design our bronze window profiles

The basic design of our bronze window profiles is actually inspired by a traditional steel factory window from a 100-year-old steelworks building in downtown San Antonio. We took a section from an old window that was being demolished, stripped back all the layers of paint and putty, and discovered a beautifully refined silhouette that continues to inspire the profile of our bronze extrusions today. Watch Trevor telling the story below:

Of course, we made some refinements of our own. We took that very old design with its simple shape and adapted it into a 21st century window frame system that is not just visually elegant, but also thermally broken for optimal energy efficiency.

We found a mill using recycled bronze to precision manufacture our extrusions. In doing so, we were able to develop a bespoke manufacturing process so we can create bronze windows in almost any size and shape, and offer a range of opening and closing systems including conventional hinged windows and doors as well as bifold, sliding and pivot options.

For architects and homeowners, this means there’s virtually no limit to what can be achieved; we’ll work with you to bring your vision to life. Of course, this raises the question ‘what about cost?’ – but thanks to efficiencies in our manufacturing process, and the relatively low cost of ownership, bronze windows compare very favorably against steel.

What are sightlines and why do they matter?

One of the main reasons architects choose metal windows – and bronze in particular – is because of their narrow sightlines. In layman’s terms, this simply means how slim their frames and muntin bars are.

Bronze is an extremely hard yet also ductile alloy, which means it can be extruded into very fine, slender lengths without losing strength or structural integrity. As a result, you need less bronze to make a window frame, and that frame will be incredibly slim, with slender muntin bars.

From an architectural standpoint, this means that when you look at a building elevation, the window frames don’t overpower the other design elements – they are wonderfully delicate and subtle, with a smaller bronze-to-glass ratio that maximizes the impact of reflection and creates a façade that changes constantly depending on the season and the light.

Inside, narrow sightlines offer unobstructed views of the landscape beyond – there are no chunky, clunky window frames getting in the way. Narrow sightlines also help to maximize natural light inside a building, and the shadows they cast on sunny days are fine and delicate.

Why should I specify genuine muntins?

It’s a common misconception that muntin bars are purely decorative and that therefore, there’s no point paying more for a window with genuine muntins.

Genuine muntin bars are those that physically divide the window into smaller panes of glass – known as true divided lites. Faux muntins are simply applied to the surface of a single large pane, to make it look like a series of smaller panes.

The difference between genuine and faux muntin bars really comes down to how the glass interacts with the light. Each individual pane will have a fractionally different angle and this creates nuanced reflections that lend incredible character to both historic and contemporary properties.

What are the finish options for solid bronze windows?

One of the most appealing characteristics of natural bronze windows is that they never need to be galvanized, powder coated or painted – they’ll stay looking beautiful for generations with just some simple cleaning to remove surface dirt.

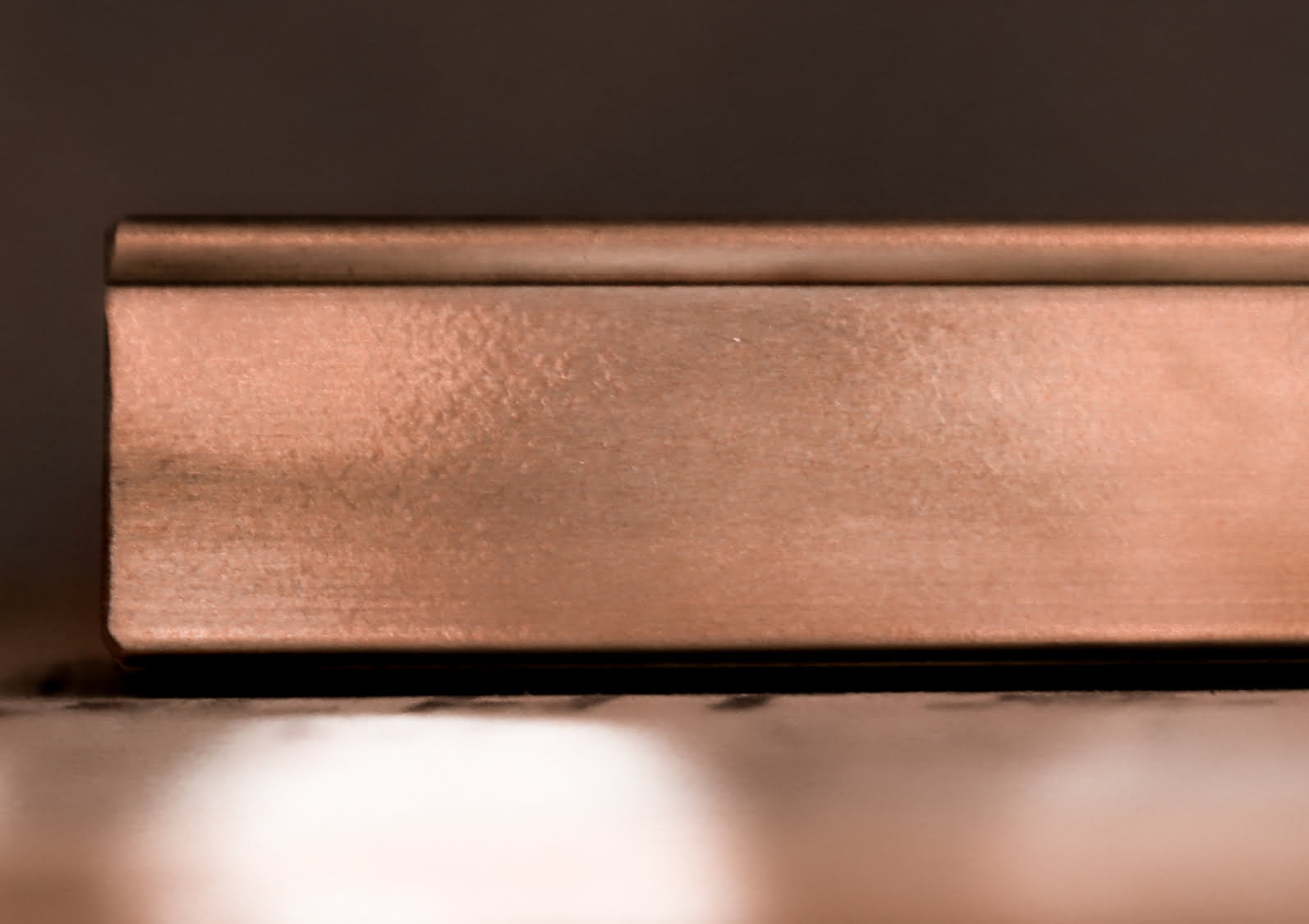

But this doesn’t mean you can’t tailor bronze windows to suit a particular color scheme or aesthetic. All bronze surfaces will develop a unique patina over time depending on the environment they’re in. We’ve harnessed this natural process and standardised it in the workshop so that we can offer our bronze architectural products in five natural patina shades – natural brushed, natural unbrushed, chestnut, slate and charcoal.

The patina process involved placing the bronze extrusions in a chemical bath, with a slightly different formula for each color. This dramatically accelerates the natural oxidation process, transforming the color of the bronze in minutes while providing a smooth, uniform finish. The patina behaves exactly the same as it would if it had developed naturally, protecting the metal underneath from corrosion even in coastal locations and eliminating the need for painting or treatments throughout its lifetime.

Got a project you’d like to discuss?

If you’re considering bronze windows for an upcoming architectural project and you’d like to know more about the design possibilities or the typical costs, we’d love to speak with you. Get in touch today for a consultation with our Architectural Sales Specialist, John Markham.