When we talk about windows, we’re usually referring to our custom, solid bronze window frames, because that’s what we design and manufacture – but of course, a window isn’t a window without the glass.

Glazing is an integral part of our manufacturing process at Renaissance, and the glass we install into our window frames plays an important role aesthetically, structurally, and practically in terms of weatherproofing and thermal performance.

We work closely with architects to develop bespoke window frame systems for both residential and commercial projects, and we offer a range of glazing options to help them achieve the visual effects and efficiency performance they’re looking for.

In this blog, we’ll explore the glazing method we use here at Renaissance, as well as the different glass specifications we offer, plus the lowdown on some special glazing finishes and treatments for specialty projects.

Our glazing method

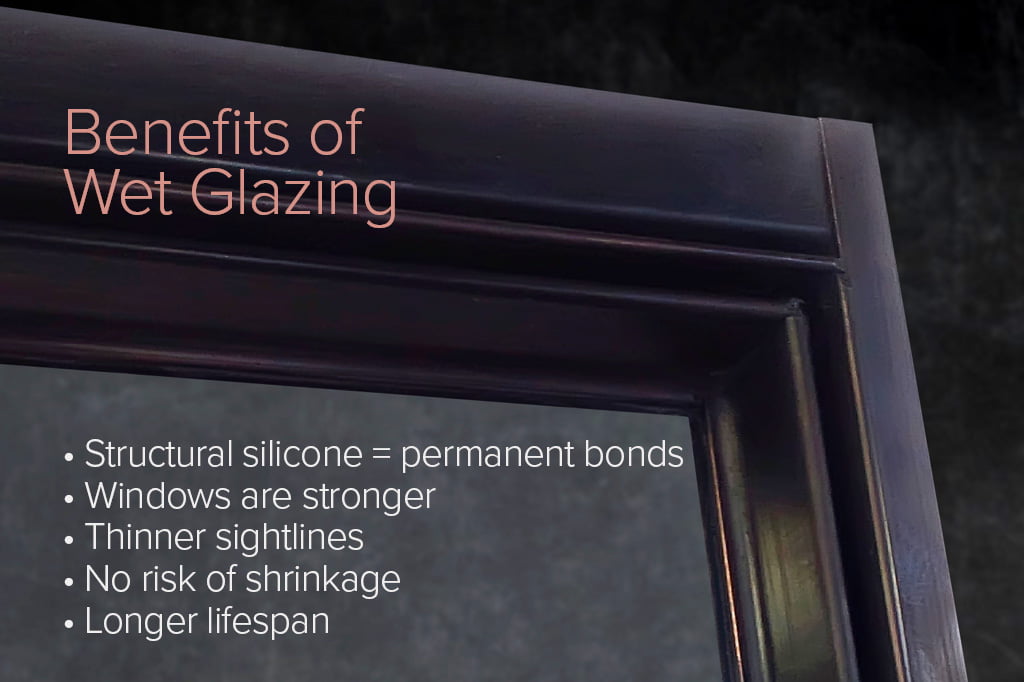

Renaissance GSB windows, doors and enclosures systems are all glazed using the wet glazing method.

Wet glazing has been around since the very first windows were made using putty to hold the glass in place. Today, we use a high-performance DOW 995 silicone bonding to adhere the glass into the glazing channel of the window, simultaneously holding it in place and sealing it against the elements.

The alternative to wet glazing is dry glazing. This is where the glass is held in place with a rubber or vinyl gasket; a strip fitted between the frame and the glass to hold it tightly in place.

Is wet glazing better than dry glazing?

Wet glazing is regarded as superior to dry glazing, the latter typically being used in cheaper window systems due to lower material and labor costs.

The gaskets used in dry glazing depend on pressure from the window to keep water out – but over time, exposure to the elements can cause them to shrink or even perish, allowing that tight seal to loosen and risking moisture ingress.

With the wet glazing method, the use of a structural silicone in liquid form means there are no spaces inside the glazing channel where moisture can accumulate. Once set, the silicone forms a crosslinked bond between the bronze and the glass, effectively rendering them as a single piece. This makes wet glazed windows much more resistant to weathering.

Wet glazed panels are also inherently stronger because the load bearing capacity of the glass and the bronze are combined. As a result, we’re able to use thinner glass on our wine cellar and shower doors for reduced weight and improved sightlines.

Key properties of glazing

The principal role of glazing in a window is to make it weathertight while allowing natural light to enter. This not only means preventing wind and water from getting in, but also preventing the transfer of heat into and out of the building, therefore making sure it is energy efficient.

The secondary function of glazing is to control the vista both into and out of a building. Great architecture uses windows to frame beautiful landscapes, create a feeling of airiness and space, and connect the indoors to the outside – but it also has an important function in terms of ensuring privacy.

Let’s take a look at some of the key things to consider when selecting a glazing profile.

Visible Light Transmittance (VLT)

Visible light transmittance (VLT) is the amount of light in the visible spectrum that passes through a glazing material. Expressed as a percentage, it is key to ensuring a building has enough natural light, which in turn impacts on energy usage.

Visible light transmittance is influenced by the glazing type, the number of panes, and any glass coatings. It ranges from above 90% for clear glass to less than 10% for glazing with highly reflective coatings or tinted glass. The insulated glass we typically specify for exterior windows and doors has a VLT of 62%.

Solar Heat Gain Coefficient (SHGC)

The solar heat gain coefficient of glass refers to the amount of short-wave radiation from sunlight that can pass through the glass, creating a ‘greenhouse’ effect inside the building.

Think about your car on a sunny day. As the sun shines in, short wave radiation passes through the glass and causes the seats and the dashboard to heat up. These objects begin to emit heat of their own – but in long waves, that can’t pass through glass. Thus, heat gets trapped inside the car and it gets very hot very quickly.

The same unwanted effect can happen inside your home without the use of Low-Emissivity (Low-E) coatings that reflect the sun’s rays outward. The Solar Heat Gain Coefficient of glass is also expressed as a percentage, and a lower number is better. The glass we use most often for our windows has a SHGC of 27%.

U-value

U-value is a measure of a window’s insulating performance and is important for code compliance. It refers to the thermal conductivity of glass in the same way as R-value refers to the thermal conductivity of a wall. These numbers are the mathematical inverse of each other – so a higher R-value is more insulating, while a LOWER U-value is more insulating.

The practical importance of U-value varies depending on location. At more northerly latitudes, a large swing in temperatures across the seasons means U-value is vital for maintaining comfortable, energy efficient homes. In more temperate climates where the temperature doesn’t fluctuate so much, but where there’s a lot of sunlight, the SHGC of a window may take priority over U-value.

Reflectance value: Double vs triple glazing

A trend towards ultra-energy-efficient homes means we’re often asked about triple glazed windows, which undoubtedly have some impressive thermal properties. We can and do supply triple glazed bronze windows on request, but we don’t recommend them – and here’s why.

First of all, triple glazed windows have an extra pane and an extra set of seals, which means they have greater potential for failure in the long term – and they are extremely expensive to replace.

Secondly, triple glazed windows have a much higher reflectance value or Visible Light Reflectance (VLR). This refers to the amount of light that gets reflected off the glass as you look at it, and whether you can see into the building, or whether the windows act like a mirror.

A higher VLR has the effect of making a building look more austere and less inviting, which is an undesirable trait of triple-glazed windows and perhaps one of the single most significant changes in architecture over the last few decades.

If you’re working on a restoration project, or you simply want a property to have some authenticity and charm, you want to eliminate reflectance as much as possible. Certain glass treatments and coatings can enhance the performance of double-glazed windows to similar levels as triple glazed, without influencing VLR.

Glass treatments and coatings

The glass sheets used to make prefabricated insulated glazing units can be subjected to a range of different processes that alters their thermal and light conductivity properties. It’s possible to make glass more or less reflective, or add strength by adding other materials to the glass.

Tempering

Tempered glass (also sometimes called toughened glass) has been heat treated to make it stronger. This is required for code compliance in certain situations, for example on glass doors where there would be a safety problem if the glass breaks. At Renaissance, we supply ALL our windows, doors, and enclosure systems with tempered glass fitted as standard, exceeding code requirements.

Laminating

Laminated glass is comprised of at least two layers of thin glass which are permanently bonded together using a plastic interlayer material. The most common example of laminated glass is a car windshield. The plastic layer serves to hold the glass together even if it’s smashed.

Laminated glass also has significant noise reduction properties. It’s most commonly used for storm glass in hurricane zones, but also sometimes for security or anti-vandalism purposes.

Low-E glass

Low emissivity glass is designed to prevent solar radiation from passing through and heating up the interior of a building. It is made by applying layers of microscopic silver particles to the surface of the glass, which block the sun’s rays while still allowing the glass to look transparent to the human eye.

Soft vs hard Low-E coatings

Low-E coatings are referred to as ‘soft’ which is a surface applied coating, or ‘hard’ or pyrolytic coatings, which are physically baked into the surface of the glass. In a double-glazed unit, the soft coating is normally applied to the back of the exterior pane of glass (known as the outboard lite) where it is protected from scratches and cleaning solvents etc.

Hard Low-E coatings can be applied to the room-facing pane (the inboard lite) because they are less vulnerable to abrasion. This has the effect of preventing heat loss from the inside the building. Combining Low-E coatings on BOTH the inboard and outboard lites of a double-glazed unit can accrue energy savings that put these systems on a par with triple glazed units, with no compromise on VLR, no additional weight and significant cost savings.

What glass sizes are available?

We can provide glazing in a large range of sizes and specifications, from standard glazing units through to oversized glass. The larger the glass is, the more likely it is that a custom frame profile will be required to accommodate its weight and also a deeper ‘glass bite’, which refers to the amount of glass that needs to be held within the actual frame.

The glazing we supply typically falls into one of the following tiers:

| Tier 1- RGSB Standard | Tier 2 | Tier 3 |

|---|---|---|

| Guardian 62/27 glass Dual pane Tempered Low-E Standard Renaissance profile & frame Up to 55 sq ft Max dimension 1: 78” Max dimension 2: 128” | Custom glazing spec Standard or custom Renaissance profile & frame 55-128 sq ft Max dimension 1: 96” Max dimension 2: 192” | Custom glazing spec Custom Renaissance profile & frame 128-216 sq ft Max dimension 1: 130” Max dimension 2: 240” |

Specialty glass

On occasions, we’re asked to provide windows or enclosure systems with specialty glazing for a specific location or application. We work very closely with our specialist glazing partners to ensure we can deliver the best solution for our clients’ needs.

Turtle glass

Spare a thought for the architects of Florida, who not only have to worry about hurricanes destroying the homes they build but also have to concern themselves with the needs of sea turtle hatchlings. Baby turtles hatch at night and instinctively follow the moon towards water, but seafront homes with large windows can confuse them, drawing them up the beach where they fall victim to predators, instead of out to sea.

Turtle glass has a maximum VLT of 45% and is used to limit the amount of light emanating from seafront homes after dark. It is a legal requirement for seafront homes in many Florida municipalities.

UV glass

Ultraviolet light passing through windows can cause damage to interior surfaces – it’s likely you’ve noticed how soft furnishings or wallpaper exposed to sunlight through a window get faded over time. UV glass is designed to protect against this type of damage by blocking UV light from the sun.

UV glass for wine cellars

At Renaissance, the most common application for UV glass is for our wine cellar doors. Direct exposure to UV light is bad for wine, causing a chemical reaction that can make it taste acidic (known as ‘light struck’ wine). UV glass is installed in wine cellars that are exposed to direct sunlight through the exterior windows of a home, which is common in open-plan homes in sunny locations.

UV glass exterior windows

UV glass can also be used for exterior windows where there is a need to protect interior finishes, or items such as valuable artwork, from the bleaching effects of sunlight.

Need advice on glazing?

After 20 years as a window manufacturer, we’ve amassed considerable knowledge around glazing specifications and built strong partnerships with glazing specialists, including manufacturers and engineers. If you have questions about a particular glazing challenge, chances are we’ll know the answers – but if we don’t, we have access to experts that do. Contact us today to discuss the parameters of your upcoming project.

For those interested in broader architectural possibilities, explore our Custom Bronze Designs for Architects to see how we integrate sophisticated glazing with cutting-edge bronze design.

Frequently Asked Questions

What is the difference between wet glazing vs dry glazing?

Wet glazing uses liquid sealants to bond glass directly into the frame, while dry glazing uses pre-formed rubber gaskets to hold the glass tightly in place. Wet glazing has a number of advantages over dry glazing.

The primary advantage is weathertightness. Dry glazed windows are prone to shrinkage over time – the gaskets dry out and shrink or decay with exposure to the elements, leading to heat loss and moisture ingress.

Wet glazed windows are also stronger – the silicone used to bond the glass into the frame forms crosslinked bonds which lend structural integrity – allowing for larger, lighter windows, ensuring window frames stay perfectly in square, and reducing the risk of broken panes later on.

Our windows are factory glazed and arrive on site ready for installation, which significantly speeds up and de-risks this process. And since life happens, we’ve made it simple to replace broken window panes on our bronze windows by creating a removable stop system. There’s no need to drop out the whole unit – easy access to the stops means you can just replace the broken pane vertically for total convenience.

How do U-value, SHGC, and VLT affect glazing performance?

Visible light transmittance (VLT) is the amount of light in the visible spectrum that passes through glass. It ranges from above 90% for clear glass to less than 10% for glazing with highly reflective coatings or tinted glass.

U-value is a measure of a window’s insulating performance and is important for code compliance. It refers to the thermal conductivity of glass – the lower the U-value, the more insulating the glass.

The Solar Heat Gain Coefficient of glass refers to the amount of short-wave radiation from sunlight that can pass through the glass, creating a ‘greenhouse’ effect inside the building. SHGC is expressed as a percentage, and a lower number is better.

Together, these metrics guide architects in balancing efficiency, comfort, and aesthetics.

Can specialty glass coatings impact visual clarity or maintenance?

Yes. Specialty coatings like Low-E or laminated glass improve performance by enhancing insulation, safety, and sound reduction. In most cases, they maintain excellent visual clarity, though some coatings may slightly alter reflectivity or tint – for example, our wine safe glass has a UV coating that blocks 99.9% of sunlight, but it does have a slight tint. Maintenance is straightforward -coatings are typically applied on the inward-facing sides of double-glazed windows so the outward-facing sides can be cleaned as normal. Check out our blog for more details about glass coatings.

How are large glass sizes handled in bronze frames, and what are the limits or structural considerations?

Our custom bronze window frames are engineered to support large glass sizes, making them ideal for expansive views and full-height window walls. Maximum dimensions depend on the profile and project requirements. A key feature of bronze windows is their ratio of size and strength to material volume and weight. With a bronze window, it’s possible to achieve equivalent or greater structural strength using less material than a steel window of the same dimensions, which means our frames can be thinner and lighter – allowing for uninterrupted views and greater architectural flexibility. Our team works closely with architects to ensure that oversized glazing meets performance, safety, and design goals.