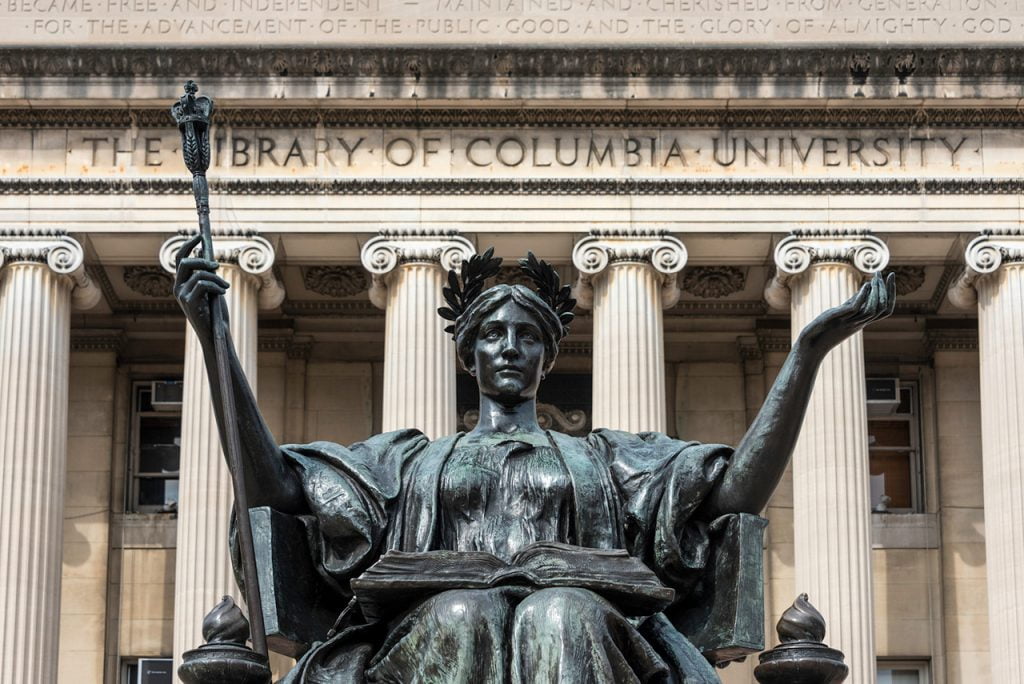

When we refer to ‘bronze patina’, most people will automatically think of a rich brown hue, or even a grayish green – the color we’re used to seeing on bronze statues that have been exposed to the elements for many years.

And it’s true – this deep brown or greenish color (sometimes called Verdigris, from the French for gray-green) – is the natural patina finish that develops on a bronze surfaces over time. But did you know that the natural patina process can be manipulated to influence the final color?

In this blog, we’ll dive into the fascinating world of patina – how and why it forms, and how we harness the science to create our heritage-grade products.

What is bronze patina?

Bronze patina is a protective layer that forms on the surface of bronze. It is caused by oxidation of some of the compounds that make up the bronze alloy (typically copper, iron, lead and zinc) as they are exposed to elements in their environment (air, rain, salts, oils etc).

Unlike rust, which is also caused by oxidation, bronze patina is a desirable finish because once formed, it ultimately protects the metal underneath from further oxidation. This means that solid bronze can and does last for centuries, even in exposed locations.

The final color of bronze patina is determined by the composition of the bronze itself. The more copper in the alloy, the more green the final color will be, so it’s important to understand what grade of bronze you’re buying, and what you can expect from the finish over time.

What is architectural bronze?

Architectural bronze is a specific grade of bronze alloy designed for optimal hardness and durability over time. It typically has a composition as follows:

- Copper (Cu): 57-59%

- Zinc (Zn): 39-41%

- Lead (Pb): 0.5-3%

- Iron (Fe): 0.1-1%

- Manganese (Mn): Up to 1%

Alternatives to architectural bronze are statuary bronze, which is most suitable for casting, and commercial bronze, which is of a lesser quality – it’s usually softer, with a high copper content. If you were to purchase bronze windows and doors made from commercial-grade bronze, you might find that they develop a heavy Verdigris coating due to the high copper content, requiring regular, expensive refinishing to keep it at bay.

We only use architectural-grade bronze for our windows, doors, and enclosure systems.

Our finishes: How we control the patina process

Natural bronze is sometimes referred to as a ‘living finish’. This means that it will change organically over time, and there’s no way to predict exactly how it will look during this process.

Before a raw bronze extrusion reaches its final deep brown color with those distinctive hints of green and gold, it will go through a process of gradual mottling and darkening. For many people, this organic process is a big part of the appeal of bronze, and they are happy to allow nature to take its course.

Others prefer a more consistent, controllable finish – particularly when the color of the windows and doors is integral to the overall design of a property. Therefore, we offer our bronze products in a range of different patina finishes that are produced under controlled conditions in our workshop.

This process works by dipping the bronze extrusions into a chemical bath containing a specific solution that causes the metal to oxidise in minutes, not years. The composition of the solution varies depending on what color patina we want to produce, and we offer three different shades – chestnut, slate and charcoal – in addition to natural and custom finishes.

Are bronze windows maintenance-free?

There’s really no such thing as 100% maintenance-free windows. Like any other material, bronze windows will require cleaning to remove dust, grime, moss and other debris that can accumulate over time.

However, bronze windows are much lower maintenance than the typical alternative, which is a galvanised steel window.

Our ‘man made’ patina finish is exactly the same as the protective patina layer that would develop naturally over time – the only difference is that we can influence the speed, color and uniformity of the finished result. It protects the bronze from corrosion (rust) for decades, if not centuries, with no reapplication, painting or lacquering required.

It’s very important to say that even after being patinaed in our workshop, our bronze products still have a living finish and will continue to change over time. However, because the surface is darker to begin with, these effects are much more subtle and consistent.

What about natural bronze?

We offer our customers the option to commission bronze windows, doors and enclosure systems in natural bronze with a brushed or unbrushed finish. These extrusions do not undergo a patina process – they are simply assembled in their raw state, or given a semi-matte, brushed sheen.

To begin with, natural bronze has a golden hue with pinkish undertones. Over time it will mottle and darken until eventually it reaches a dark brown color with Verdigris accents and the golden color perhaps peeking through on edges or door furniture that becomes burnished through daily handling.

Sometimes, especially for indoor installations like bronze shower doors, internal doors and wine cellar enclosures, the client may wish stop this process from occurring and retain the golden color of the bronze in perpetuity.

In this case, we apply a clear lacquer to the natural bronze to prevent it from coming in direct contact with air, moisture and other elements that cause it to oxidise. This lacquer typically lasts around 20-50 years before needing to be reapplied.

Other finishes we offer

Occasionally, a client will opt for bronze windows not because they love the look or the natural character of a patina finish, but because their project demands an extremely long-lasting, corrosion-resistant system.

In these situations, we can provide a powder-coated finish in a variety of colors, enabling a bronze window or door set to blend easily with existing steel windows or other design elements.